Our fashionable lives rely upon uncommon earth components, and sometime quickly we could not have sufficient to fulfill rising demand.

Because of their particular properties, these 17 metallic components are essential substances in pc screens, cell telephones and different electronics, compact fluorescent lamps, medical imaging machines, lasers, fiber optics, pigments, sprucing powders, industrial catalysts – the record goes on and on (SN Online: 1/16/23). Notably uncommon earths are a vital a part of the high-powered magnets and rechargeable batteries within the electrical autos and renewable vitality applied sciences wanted to get the world to a low- or zero-carbon future.

Science News headlines, in your inbox

Headlines and summaries of the newest Science News articles, delivered to your e mail inbox each Thursday.

Thank you for signing up!

There was an issue signing you up.

In 2021, the world mined 280,000 metric tons of uncommon earths — roughly 32 instances as a lot as was mined within the mid-Nineteen Fifties. And demand is barely going to extend. By 2040, specialists estimate, we’ll want as much as seven instances as a lot uncommon earths as we do at this time.

Satisfying that urge for food gained’t be straightforward. Rare earth components will not be present in concentrated deposits. Miners should excavate large quantities of ore, topic it to bodily and chemical processes to pay attention the uncommon earths, after which separate them. The transformation is vitality intensive and soiled, requiring poisonous chemical compounds and infrequently producing a small quantity of radioactive waste that should be safely disposed of. Another concern is entry: China has a close to monopoly on each mining and processing; the United States has only one energetic mine (SN Online: 1/1/23).

For a lot of the jobs uncommon earths do, there aren’t any good substitutes. So to assist meet future demand and diversify who controls the availability — and maybe even make uncommon earth restoration “greener” — researchers are searching for options to traditional mining.

Proposals embrace every thing from extracting the metals from coal waste to essentially out-there concepts like mining the moon. But the method most certainly to make a right away dent is recycling. “Recycling is going to play a very important and central role,” says Ikenna Nlebedim, a supplies scientist at Ames National Laboratory in Iowa and the Department of Energy’s Critical Materials Institute. “That’s not to say we’re going to recycle our way out of the critical materials challenge.”

Still, within the uncommon earth magnets market, as an illustration, by about 10 years from now, recycling might fulfill as a lot as 1 / 4 of the demand for uncommon earths, primarily based on some estimates. “That’s huge,” he says.

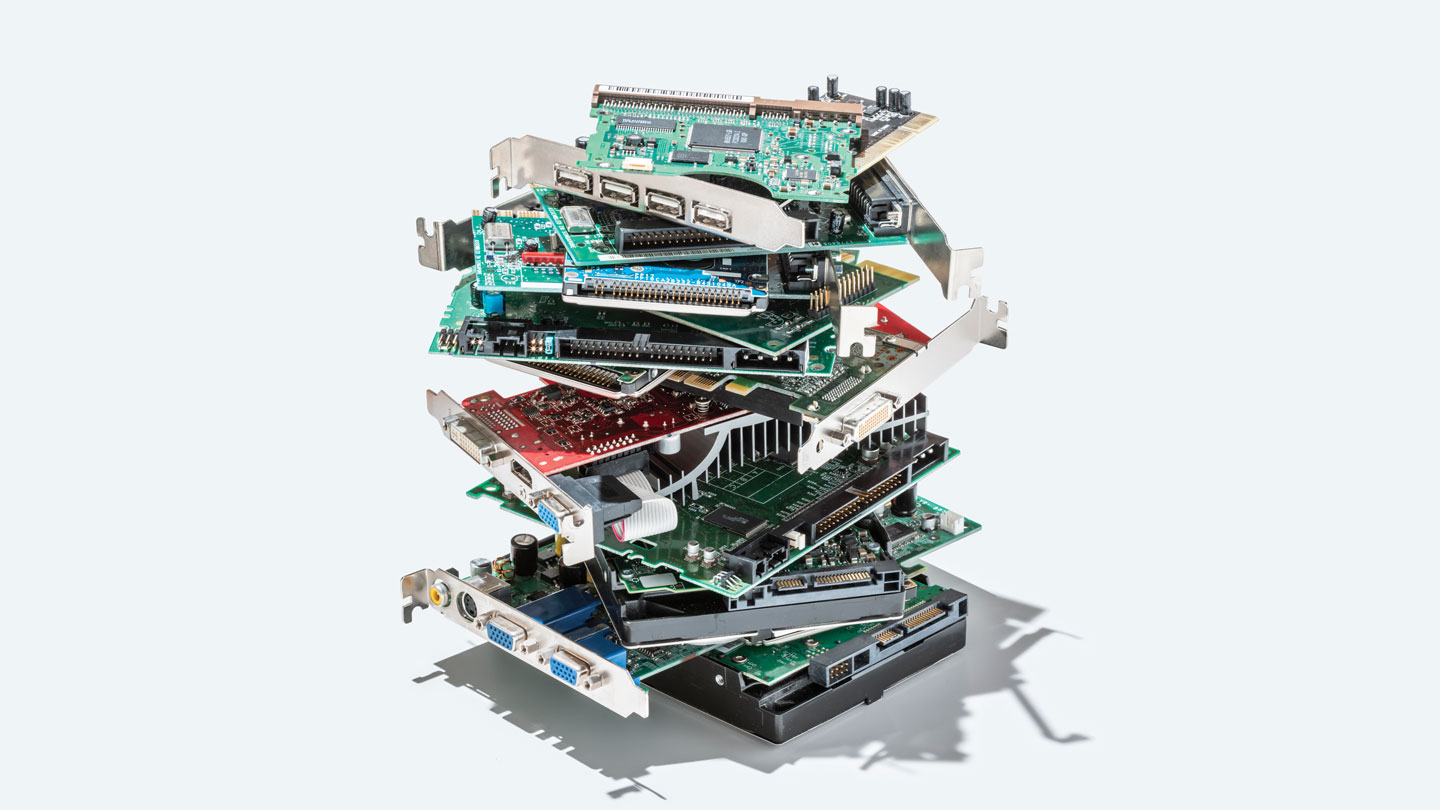

But earlier than the uncommon earths in an outdated laptop computer will be recycled as commonly because the aluminum in an empty soda can, there are technological, financial and logistical obstacles to beat.

Why are uncommon earths so difficult to extract?

Recycling looks like an apparent solution to get extra uncommon earths. It’s normal observe within the United States and Europe to recycle from 15 to 70 % of different metals, reminiscent of iron, copper, aluminum, nickel and tin. Yet at this time, solely about 1 % of uncommon earth components in outdated merchandise are recycled, says Simon Jowitt, an financial geologist on the University of Nevada, Las Vegas.

“Copper wiring can be recycled into more copper wiring. Steel can just be recycled into more steel,” he says. But lots of uncommon earth merchandise are “inherently not very recyclable.”

Rare earths are sometimes blended with different metals in contact screens and related merchandise, making elimination tough. In some methods, recycling uncommon earths from tossed-out gadgets resembles the problem of extracting them from ore and separating them from one another. Traditional uncommon earth recycling strategies additionally require hazardous chemical compounds reminiscent of hydrochloric acid and lots of warmth, and thus lots of vitality. On high of the environmental footprint, the price of restoration is probably not definitely worth the effort given the small yield of uncommon earths. A tough disk drive, as an illustration, may include just some grams; some merchandise supply simply milligrams.

Chemists and supplies scientists, although, are attempting to develop smarter recycling approaches. Their methods put microbes to work, ditch the acids of conventional strategies or try to bypass extraction and separation.

Microbial companions can assist recycle uncommon earths

One method leans on microscopic companions. Gluconobacter micro organism naturally produce natural acids that may pull uncommon earths, reminiscent of lanthanum and cerium, from spent catalysts utilized in petroleum refining or from fluorescent phosphors utilized in lighting. The bacterial acids are much less environmentally dangerous than hydrochloric acid or different conventional metal-leaching acids, says Yoshiko Fujita, a biogeochemist at Idaho National Laboratory in Idaho Falls. Fujita leads analysis into reuse and recycling on the Critical Materials Institute. “They can also be degraded naturally,” she says.

In experiments, the bacterial acids can recuperate solely a few quarter to half of the uncommon earths from spent catalysts and phosphors. Hydrochloric acid can do a lot better — in some instances extracting as a lot as 99 %. But bio-based leaching may nonetheless be worthwhile, Fujita and colleagues reported in 2019 in ACS Sustainable Chemistry & Engineering.

In a hypothetical plant recycling 19,000 metric tons of used catalyst a yr, the group estimated annual revenues to be roughly $1.75 million. But feeding the micro organism that produce the acid on-site is an enormous expense. In a state of affairs by which the micro organism are fed refined sugar, complete prices for producing the uncommon earths are roughly $1.6 million a yr, leaving round simply $150,000 in income. Switching from sugar to corn stalks, husks and different harvest leftovers, nevertheless, would slash prices by about $500,000, elevating income to about $650,000.

One experimental recycling method makes use of natural acids made by micro organism to extract uncommon earths from waste merchandise. This reactor on the Idaho National Laboratory prepares an natural acid combination for such recycling.Idaho National Lab

Other microbes may also assist extract uncommon earths and take them even additional. A couple of years in the past, researchers found that some micro organism that metabolize uncommon earths produce a protein that preferentially grabs onto these metals. This protein, lanmodulin, can separate uncommon earths from one another, reminiscent of neodymium from dysprosium — two elements of uncommon earth magnets. A lanmodulin-based system may eradicate the necessity for the numerous chemical solvents sometimes utilized in such separation. And the waste left behind — the protein — can be biodegradable. But whether or not the system will pan out on a industrial scale is unknown.

How to drag uncommon earths from discarded magnets

Another method already being commercialized skips the acids and makes use of copper salts to drag the uncommon earths from discarded magnets, a invaluable goal. Neodymium-iron-boron magnets are about 30 % uncommon earth by weight and the one largest software of the metals on the earth. One projection means that recovering the neodymium in magnets from U.S. exhausting disk drives alone might meet up about 5 % of the world’s demand outdoors of China earlier than the tip of the last decade.

Nlebedim led a group that developed a way that makes use of copper salts to leach uncommon earths out of shredded digital waste that incorporates magnets. Dunking the e-waste in a copper salt answer at room temperature dissolves the uncommon earths within the magnets. Other will be scooped out for their very own recycling, and the copper will be reused to make extra salt answer. Next, the uncommon earths are solidified and, with the assistance of extra chemical compounds and heating, reworked into powdered minerals referred to as uncommon earth oxides. The course of, which has additionally been used on materials left over from magnet manufacturing that sometimes goes to waste, can recuperate 90 to 98 % of the uncommon earths, and the fabric is pure sufficient to make new magnets, Nlebedim’s group has demonstrated.

In a best-case state of affairs, utilizing this technique to recycle 100 tons of leftover magnet materials may produce 32 tons of uncommon earth oxides and internet greater than $1 million in income, an financial evaluation of the strategy suggests.

That examine additionally evaluated the method’s environmental impacts. Compared with producing one kilogram of uncommon earth oxide through one of many primary varieties of mining and processing presently utilized in China, the copper salt technique has lower than half the carbon footprint. It produces a median of about 50 kilograms of carbon dioxide equal per kilogram of uncommon earth oxide versus 110, Nlebedim’s group reported in 2021 in ACS Sustainable Chemistry & Engineering.

But it’s not essentially greener than all types of mining. One sticking level is that the method requires poisonous ammonium hydroxide and roasting, which consumes lots of vitality, and it nonetheless releases some carbon dioxide. Nlebedim’s group is now tweaking the approach. “We want to decarbonize the process and make it safer,” he says.

Meanwhile, the expertise appears promising sufficient that TdVib, an Iowa firm that designs and manufactures magnetic supplies and merchandise, has licensed it and constructed a pilot plant. The preliminary purpose is to supply two tons of uncommon earth oxides per thirty days, says Daniel Bina, TdVib’s president and CEO. The plant will recycle uncommon earths from outdated exhausting disk drives from knowledge facilities.

Noveon Magnetics, an organization in San Marcos, Texas, is already making recycled neodymium-iron-boron magnets. In typical magnet manufacturing, the uncommon earths are mined, reworked into metallic alloys, milled right into a tremendous powder, magnetized and shaped right into a magnet. Noveon knocks out these first two steps, says firm CEO Scott Dunn.

After demagnetizing and cleansing discarded magnets, Noveon instantly mills them right into a powder earlier than constructing them again up as new magnets. Unlike with different recycling strategies, there’s no must extract and separate the uncommon earths out first. The closing product will be greater than 99 % recycled magnet, Dunn says, with a small addition of virgin uncommon earth components — the “secret sauce,” as he places it — that enables the corporate to fine-tune the magnets’ attributes.

Compared with conventional magnet mining and manufacturing, Noveon’s technique cuts vitality use by about 90 %, Miha Zakotnik, Noveon’s chief expertise officer, and different researchers reported in 2016 in Environmental Technology & Innovation. Another 2016 evaluation estimated that for each kilogram of magnet produced through Noveon’s technique, about 12 kilograms of carbon dioxide equal are emitted. That’s about half as a lot of the greenhouse gasoline as typical magnets.

Dunn declined to share what quantity of magnets Noveon presently produces or how a lot its magnets price. But the magnets are being utilized in some industrial purposes, for pumps, followers and compressors, in addition to some shopper energy instruments and different electronics.

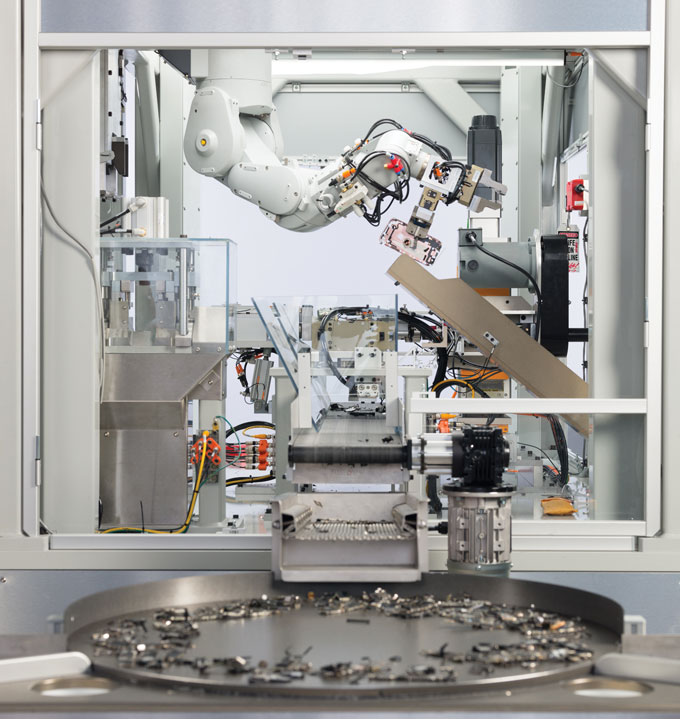

To assist with recycling, Apple developed the robotic Daisy (proven), which might dismantle 23 fashions of iPhones. Other robots within the works — Taz and Dave — will specialise in recovering uncommon earth magnets.Apple

To assist with recycling, Apple developed the robotic Daisy (proven), which might dismantle 23 fashions of iPhones. Other robots within the works — Taz and Dave — will specialise in recovering uncommon earth magnets.Apple

Rare earth recycling has logistical hurdles

Even as researchers clear technological hurdles, there are nonetheless logistical boundaries to recycling. “We don’t have the systems for collecting end-of-life products that have rare earths in them,” Fujita says, “and there’s the cost of dismantling those products.” For lots of e-waste, earlier than uncommon earth recycling can start, you must get to the bits that include these valuable metals.

Noveon has a semiautomated course of for eradicating magnets from exhausting disk drives and different electronics.

Apple can be making an attempt to automate the recycling course of. The firm’s Daisy robotic can dismantle iPhones. And in 2022, Apple introduced a pair of robots referred to as Taz and Dave that facilitate the recycling of uncommon earths. Taz can collect magnet-containing modules which might be sometimes misplaced in the course of the shredding of electronics. Dave can recuperate magnets from taptic engines, Apple’s expertise for offering customers with tactile suggestions when, say, tapping an iPhone display.

Even with robotic aids, it could nonetheless be rather a lot simpler if firms simply designed merchandise in a method that made recycling straightforward, Fujita says.

No matter how good recycling will get, Jowitt sees no getting round the necessity to ramp up mining to feed our uncommon earth–hungry society. But he agrees recycling is critical. “We’re dealing with intrinsically finite resources,” he says. “Better we try and extract what we can rather than just dumping it in the landfill.”