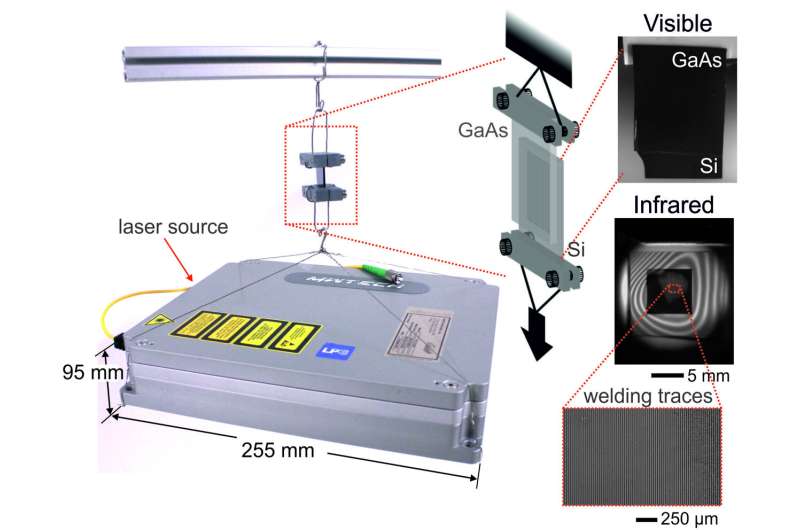

Left: Image of the laser supply employed within the experiments hanging within the air by the welding of a silicon (Si) wafer on high of a gallium arsenide (GaAs) one. The unit weighs 3 kg and the welded space is estimated to maintain as much as 400 N. Right: Images of the welded items taken by the use of a visual and an infrared digicam, which permits observing the welding sample in between. Credit: Pol Sopeña and David Grojo

Today, lasers are well-established in each day life, even whether it is generally laborious to inform what and the place they’re. As an instance, we will discover them in CD/DVD readers or medical purposes like most cancers and eye surgical procedure, being important instruments in an enormous vary of multidisciplinary fields. All of that is the results of fixed progress and improvement, from the primary Maiman’s ruby laser (1960) to the attosecond lasers, passing by means of unique, humorous demonstrations like Jell-O lasers.

In the hunt to continually get hold of extra intense sources, ultrashort lasers (with pulses within the femtosecond regime) represented a transparent breakthrough, as they allowed high-intensity supply in confined areas on the nanoscale. In specific, they permit inducing nonlinear absorption phenomena which, for example, permits domestically modifying the inside of clear supplies with a low thermal funds, not achievable with different laser sources. Some demonstrations embrace waveguides writing in glasses or creating 3D advanced patterns with polymers.

Ultrafast lasers opened the door to weld stacked clear supplies by irradiating by means of the highest one and specializing in the interface between them. The excessive depth leads to nearly instantaneous native melting and subsequent resolidification, mixing and bonding of each supplies. This was demonstrated with a number of supplies together with glasses, polymers, ceramics, and metals in numerous configurations.

While ultrafast laser welding would absolutely discover rapid purposes in microelectronics, it’s placing to comprehend that the method just isn’t straight relevant to bonding completely different semiconductor workpieces. The excessive intensities required for inside glass modification end in sturdy propagation nonlinearities in semiconductors as a result of their small bandgap, which tends to defocus and delocalize intense infrared radiation.

In order to sort out this problem, we needed to suppose exterior the field, and what at first appeared to be a step backward resulted in a profitable various. In the stealth dicing of silicon wafers, infrared nanosecond pulses are used to create defects inside silicon that later function weak factors to supply clean-edge cuts. The comparatively lengthy pulses have decrease intensities than ultrashort ones, avoiding undesired propagation nonlinearities, however on the identical time, will be absorbed at the focus by two-photon absorption. Based on this, we moved to longer pulses utilizing these inside modifications not as defects however as sturdy bonding factors.

During our first trials of welding silicon items, by using infrared imaging of the interface, we discovered an added constraint. Unless the hole on the interface is sort of nonexistent, together with optical contact situations, the excessive refractive index typical of semiconductors leads to a Fabry-Perot cavity that impedes reaching a excessive sufficient power density to soften each supplies. Thus, essentially the most intimate contact between the highest and backside supplies is important to realize profitable welding.

After establishing the appropriate situations to avoid these results, we efficiently made the primary experimental demonstration of silicon-silicon laser welding. After an optimization course of, we might later lengthen this strategy to different semiconductors similar to gallium arsenide in numerous configurations alongside silicon. Not solely did we obtain bonding between completely different workpieces, however we did so whereas reaching sturdy shear drive strengths within the order of a number of tens of MPa. These values evaluate effectively to ultrashort laser welding demonstrations of different supplies and the at present employed methods of wafer bonding.

This profitable experiment, now revealed in Laser & Photonics Reviews, confirms a technological barrier that has been definitively lifted. Compared to various strategies within the semiconductor business, a novel benefit of laser micro-welding is the power to affix parts with advanced multi-material architectures in a direct-write method that will not be doable in any other case. This ought to result in new modalities for manufacturing in electronics, mid-infrared photonics, and microelectromechanical methods (MEMS). Moreover, we envision the potential for the rising ideas of hybrid chips, together with electronics and microfluidics features for the thermal administration of essentially the most demanding micro-technologies, similar to super-computers or superior sensors.

This story is a part of Science X Dialog, the place researchers can report findings from their revealed analysis articles. Visit this web page for details about ScienceX Dialog and learn how to take part.

More data:

Pol Sopeña et al, Transmission Laser Welding of Similar and Dissimilar Semiconductor Materials, Laser & Photonics Reviews (2022). DOI: 10.1002/lpor.202200208

Dr. Pol Sopeña and Dr. David Grojo are researchers on the LP3 laboratory situated in Marseille, France. LP3 is a joint unit between the French National Center for Scientific Research (CNRS), and Aix-Marseille University. After incomes a Ph.D. at University of Barcelona, Pol Sopeña joined LP3 as a postdoctoral fellow the place he now concentrates his work on new semiconductor processing options. David Grojo is a everlasting CNRS scientist investigating new and thrilling alternatives to tailor materials properties with non-conventional radiations. His actions are funded by an ERC Consolidator Grant from the Excellence Science pillar of the European Research Council (cordis.europa.eu/undertaking/id/724480).

Citation:

Using lasers to bond semiconductor electronics parts (2022, December 5)

retrieved 5 December 2022

from https://phys.org/information/2022-12-lasers-bond-semiconductor-electronics-components.html

This doc is topic to copyright. Apart from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.