In an effort to supply an environmentally pleasant and low-waste various, researchers at MIT have pioneered a tunable approach to generate wood-like plant materials in a lab. Credit: Image courtesy of Luis Fernando Velásquez-García, Ashley Beckwith, et al

Each yr, the world loses about 10 million hectares of forest—an space in regards to the dimension of Iceland—due to deforestation. At that charge, some scientists predict the world’s forests may disappear in 100 to 200 years.

In an effort to supply an environmentally pleasant and low-waste various, researchers at MIT have pioneered a tunable approach to generate wood-like plant materials in a lab, which may allow somebody to “develop” a wood product like a desk with no need to chop down bushes, course of lumber, and many others.

These researchers have now demonstrated that, by adjusting sure chemical compounds used throughout the development course of, they’ll exactly management the bodily and mechanical properties of the ensuing plant materials, equivalent to its stiffness and density.

They additionally present that, utilizing 3D bioprinting strategies, they’ll develop plant materials in shapes, sizes, and types that aren’t present in nature and that may’t be simply produced utilizing conventional agricultural strategies.

“The thought is which you can develop these plant supplies in precisely the form that you just want, so that you need not do any subtractive manufacturing after the actual fact, which reduces the quantity of power and waste. There is plenty of potential to develop this and develop three-dimensional buildings,” says lead creator Ashley Beckwith, a latest Ph.D. graduate.

Though nonetheless in its early days, this analysis demonstrates that lab-grown plant supplies could be tuned to have particular traits, which may sometime allow researchers to develop wooden merchandise with the precise options wanted for a selected software, like excessive power to help the partitions of a home or sure thermal properties to extra effectively warmth a room, explains senior creator Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories.

Joining Beckwith and Velásquez-García on the paper is Jeffrey Borenstein, a biomedical engineer and group chief on the Charles Stark Draper Laboratory. The analysis is printed right now in Materials Today.

Planting cells

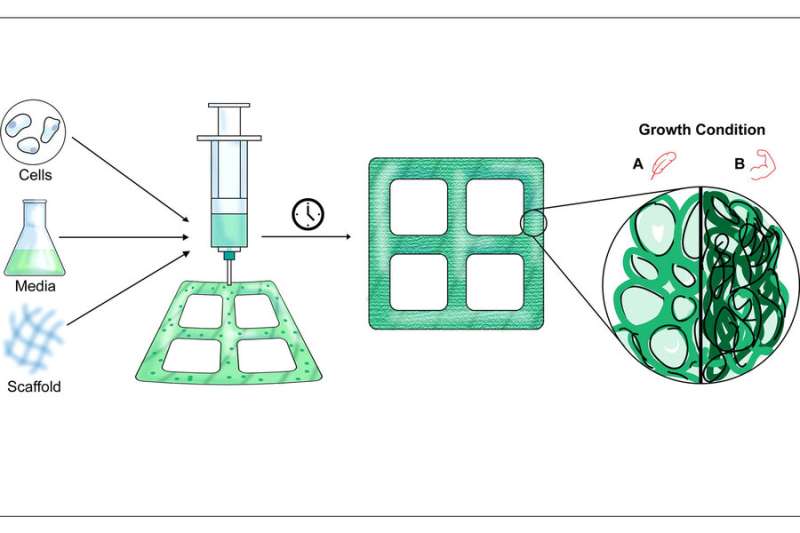

To start the method of rising plant materials within the lab, the researchers first isolate cells from the leaves of younger Zinnia elegans crops. The cells are cultured in liquid medium for 2 days, then transferred to a gel-based medium, which accommodates vitamins and two totally different hormones.

Adjusting the hormone ranges at this stage within the course of allows researchers to tune the bodily and mechanical properties of the plant cells that develop in that nutrient-rich broth.

“In the human physique, you might have hormones that decide how your cells develop and the way sure traits emerge. In the identical manner, by altering the hormone concentrations within the nutrient broth, the plant cells reply in a different way. Just by manipulating these tiny chemical portions, we will elicit fairly dramatic adjustments when it comes to the bodily outcomes,” Beckwith says.

In a manner, these rising plant cells behave nearly like stem cells—researchers may give them cues to inform them what to grow to be, Velásquez-García provides.

They use a 3D printer to extrude the cell tradition gel resolution into a selected construction in a petri dish, and let it incubate at midnight for 3 months. Even with this incubation interval, the researchers’ course of is about two orders of magnitude quicker than the time it takes for a tree to develop to maturity, Velásquez-García says.

Following incubation, the ensuing cell-based materials is dehydrated, after which the researchers consider its properties.

Wood-like traits

They discovered that decrease hormone ranges yielded plant supplies with extra rounded, open cells which have decrease density, whereas greater hormone ranges led to the expansion of plant supplies with smaller, denser cell buildings. Higher hormone ranges additionally yielded plant materials that was stiffer; the researchers have been in a position to develop plant materials with a storage modulus (stiffness) just like that of some pure woods.

Another aim of this work is to check what is called lignification in these lab-grown plant supplies. Lignin is a polymer that’s deposited within the cell partitions of crops which makes them inflexible and woody. They discovered that greater hormone ranges within the development medium causes extra lignification, which might result in plant materials with extra wood-like properties.

The researchers additionally demonstrated that, utilizing a 3D bioprinting course of, the plant materials could be grown in a customized form and dimension. Rather than utilizing a mould, the method entails the usage of a customizable computer-aided design file that’s fed to a 3D bioprinter, which deposits the cell gel tradition into a selected form. For occasion, they have been in a position to develop plant materials within the form of a tiny evergreen tree.

Research of this sort is comparatively new, Borenstein says.

“This work demonstrates the facility {that a} expertise on the interface between engineering and biology can deliver to bear on an environmental problem, leveraging advances initially developed for well being care purposes,” he provides.

The researchers additionally present that the cell cultures can survive and proceed to develop for months after printing, and that utilizing a thicker gel to supply thicker plant materials buildings doesn’t impression the survival charge of the lab-grown cells.

‘Amenable to customization’

“I believe the actual alternative right here is to be optimum with what you employ and the way you employ it. If you need to create an object that’s going to serve some objective, there are mechanical expectations to think about. This course of is admittedly amenable to customization,” Velásquez-García says.

Now that they’ve demonstrated the efficient tunability of this method, the researchers need to proceed experimenting to allow them to higher perceive and management mobile growth. They additionally need to discover how different chemical and genetic elements can direct the expansion of the cells.

They hope to judge how their methodology may very well be transferred to a brand new species. Zinnia crops do not produce wooden, but when this methodology have been used to make a commercially necessary tree species, like pine, the method would have to be tailor-made to that species, Velásquez-García says.

Ultimately, he’s hopeful this work may also help to inspire different teams to dive into this space of analysis to assist cut back deforestation.

“Trees and forests are a tremendous device for serving to us handle local weather change, so being as strategic as we will with these assets shall be a societal necessity going ahead,” Beckwith provides.

Could lab-grown plant tissue ease the environmental toll of logging and agriculture?

More data:

Ashley L. Beckwith et al, Physical, mechanical, and microstructural characterization of novel, 3D-printed, tunable, lab-grown plant supplies generated from Zinnia elegans cell cultures, Materials Today (2022). DOI: 10.1016/j.mattod.2022.02.012

Provided by

Massachusetts Institute of Technology

This story is republished courtesy of MIT News (net.mit.edu/newsoffice/), a preferred web site that covers information about MIT analysis, innovation and instructing.

Citation:

Toward customizable timber, grown in a lab (2022, May 25)

retrieved 25 May 2022

from https://phys.org/information/2022-05-customizable-timber-grown-lab.html

This doc is topic to copyright. Apart from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.