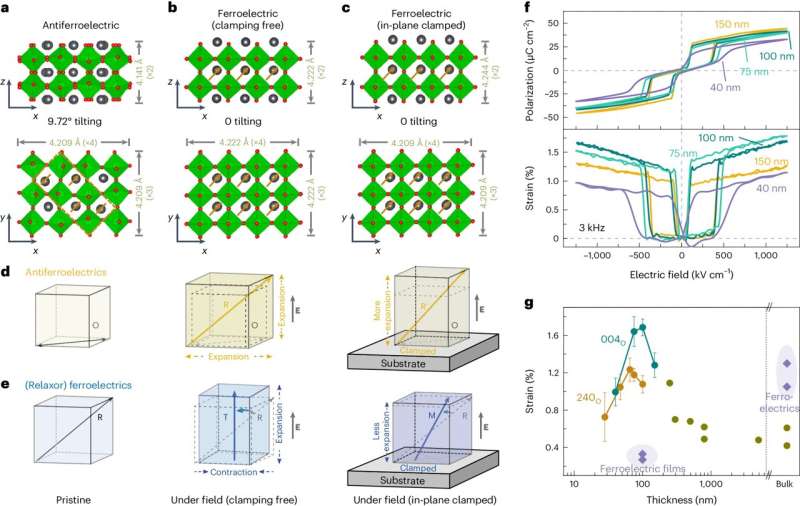

Mechanism for the enhancement of electromechanical response and abnormal thickness scaling in antiferroelectric PbZrO3 thin films. Credit: Nature Materials (2024). DOI: 10.1038/s41563-024-01907-y

Lighting a gas grill, getting an ultrasound, using an ultrasonic toothbrush—these actions involve the use of materials that can translate an electric voltage into a change in shape and vice versa.

Known as piezoelectricity, the ability to trade between mechanical stress and electric charge can be harnessed widely in capacitors, actuators, transducers and sensors like accelerometers and gyroscopes for next-generation electronics. However, integrating these materials into miniaturized systems has been difficult due to the tendency of electromechanically active materials to—at the submicrometer scale, when the thickness is just a few millionths of an inch—get “clamped” down by the material they are attached to, which significantly dials down their performance.

Rice University researchers and collaborators at the University of California, Berkeley have found that a class of electromechanically active materials called antiferroelectrics may hold the key to overcoming performance limitations due to clamping in miniaturized electromechanical systems.

A new study published in Nature Materials reports that a model antiferroelectric system, lead zirconate (PbZrO3), produces an electromechanical response that can be up to five times greater than that of conventional piezoelectric materials even in films that are only 100 nanometers (or 4 millionths of an inch) thick.

“We’ve been using piezoelectric materials for decades,” said Rice materials scientist Lane Martin, who is the corresponding author on the study. “Recently there has been a strong motivation to further integrate these materials into new types of devices that are very small—as you would want to do for, say, a microchip that goes inside your phone or computer. The problem is that these materials are typically just less usable at these small scales.”

According to current industry standards, a material is considered to have very good electromechanical performance if it can undergo a 1% change in shape—or strain—in response to an electric field. For an object that measures 100 inches in length, for instance, getting 1 inch longer or shorter represents 1% strain.

2024-05-23 19:00:02

Post from phys.org